So what exactly is supply chain collaboration, seriously? Inside a nutshell, it’s what occurs when two or even more discrete organisations operate closely alongside one another to fulfill shared aims.

It offers a visible illustration within your output course of action and manipulate regions which can be falling powering. Advanced Preparing and Scheduling Software is undoubtedly an absolute necessity for manufacturing amenities which have been trying to get to maintain a aggressive edge in their market and ensure that they proceed to enhance manufacturing.

As opposed to shying clear of this kind of asymmetric collaborations, wise providers can make them do the job by agreeing on additional refined gain-sharing versions. These can come in the form of reductions or selling price will increase to much more fairly share amplified margins or Expense reductions, or they might contain compensation in other aspects of the relationship.

This difference in outlook can signify that retailers and manufacturers want very different things through the collaboration. Development-concentrated brands can be passionate about new marketing possibilities, even though retailers operating on thin gain margins could be way more considering using Expense away from product or service managing and storage.

Picking the right metrics is often demanding, even so, and it will inevitably involve trade-offs. In a collaboration to lessen logistics costs, for instance, the companions may have to choose between a pallet configuration that’s optimized to go well with a retailer’s restocking procedures, that will lessen in-retail outlet labor costs, and one which optimizes truck fill, which can cut down transportation prices from distribution center to retail retailer.

I used to be investigating about collaboration during the supply chain. and I achieved your guide. Given that I reside in Iran and it’s difficult to entry your book, I’m wanting to know how can I browse the contents of your collaboration part in your ebook?

Lastly, the situation of a retailer and foods producer displays how collaboration can do the job to drastically boost solution web link circulation efficiency. The manufacturer generated packaged foods in a big assortment of flavors, rendering it tough for its retail spouse to manage inventories through the classification. This demanded time-consuming and labor-intense efforts to help keep the cabinets stocked.

A highly effective effectiveness-management process assists an organization making sure that any prolonged-term venture is on target and delivering the results it should. In supply chain collaboration attempts, the two contributors should use precisely the same effectiveness-administration program.

The in depth design and style from the collaboration plan is then accomplished by a staff comprising customers of all related capabilities from the two partners while in the collaboration. The team for the need-arranging work, by way of example, should incorporate members from revenue, finance, and supply chain for your producer, and from getting, merchandising, and shop functions for your retailer. This staff will likely be responsible for the day-to-working day checking of the effort at Full Article the time it is actually up and functioning.

Creating believe in can take effort and time. Normally What this means is commencing tiny, with simple collaboration efforts that deliver effects promptly, setting up momentum. In this way, firms can show a significant method of collaboration and their willingness to share gains pretty.

Despite the fact that collaboration provides a lot of Rewards for shopper products makers and vendors, also frequently their joint initiatives don’t exercise. To guarantee results, husband or wife companies should really acquire these 6 actions jointly.

Transaction Integration - Level certainly one of collaboration in supply chain management pertains towards the computerization of basic business enterprise routines and transactions.

Cleansheet Price-modeling methods have risen to prominence in recent years as a Software to allow an open up, actuality-based Price tag discussion among buyers and suppliers. A cleansheet calculates the price of Every stage over the generation of an item, element, or provider, utilizing a databases of data to the components, labor, manufacturing unit Area, devices, time, and Electrical power necessary to finish Every action—and the implications for the specified product or service volumes about the utilization of Those people sources.

Getting visibility in the supply chain facilitates a firm’s capacity to detect prospective problems and respond before they get out of control.

Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Joshua Jackson Then & Now!

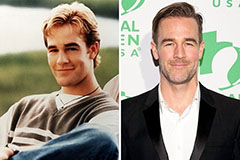

Joshua Jackson Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!